Machine Vision System

: Case study of quality control uses object recognition from chain code and moment.

FUANGROD Todsaporn

King Mongkut's Institute of Technology Ladkrabang, Thailand .

Hardware Lab, department of Computer engineering ,3D/1.

INTRODUCTION

When determining the need for and the implementation of a machine vision system, there are many important factors to consider. Machine vision systems (also referred to as “automated visual inspection systems”) typically contain a wide array of components that can directly affect the system's performance. To take full advantage of these powerful systems, and painlessly integrate them into your manufacturing line, it is the best way to take time to learn the basics about what makes up a vision system, how it is implemented, and the importance of proper planning.

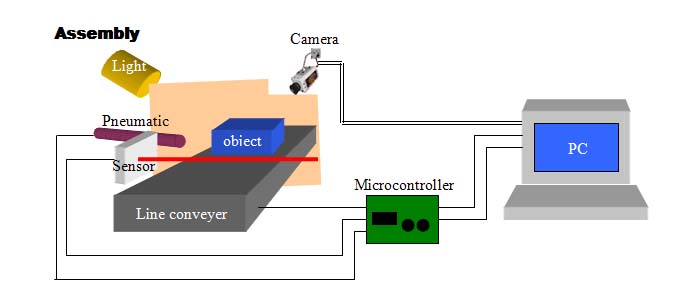

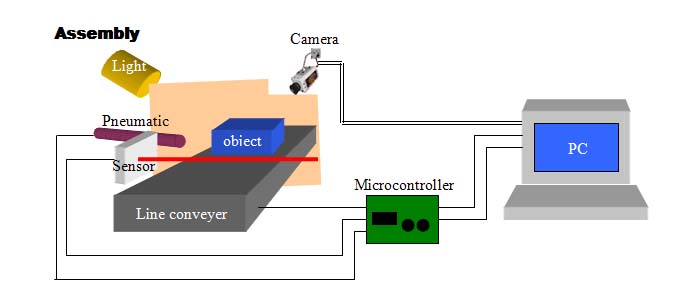

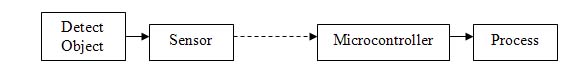

This paper concerns the studying image processing, object recognition for high quality control in the line production. The research consists of device 2 parts, the first is hardware (such as line conveyer, microcontroller, sensor, Pneumatic) and the second is software that use image processing theory and interfacing HW and SW. Image is processed by color ,edge of object and compare original object.

Sharp GP2D15 Distance Measuring Sensor

The infrared distance is measured by sensor. Digital output which reads high when an object is closer than 24cm. This sensor uses a hard-to-find 3-pin JST connector. For your convenience, we highly recommend purchasing a pre-made cable with connector, which mates with this sensor.

Pneumatic

The Pneumatic is controlled by solenoid valve type 5/2 and relay 12 V. for trig signal. Pneumatic uses for reject wrong products, after process by image processing and signal via microcontroller .

Line conveyer

|

Consist to motor ¼ hp, speed of rotation is 1450 rpm. It combines gears for decease speed of rotation to 24.1 rpm. It is work because signal from Microcontroller, control by Triac (relay 220V.)

|

Lighting

Lighting needs to illuminate the part so that the best possible image can be

acquired by the camera. Lighting assemblies come in various shapes and sizes and are

available in a variety of intensities.

MSC51 (microcontroller)

|

Controlling all part, sensor, Pneumatic and line conveyer defined by microcontroller. This MSC51 communicate between PC and MSC51 uses RS323 via serial port. MSC51 has 2 lines for connect to PC, send data and receive data. PC connects directly to camera. Camera capture picture by software in PC. MSC51 circuit made by myself. |

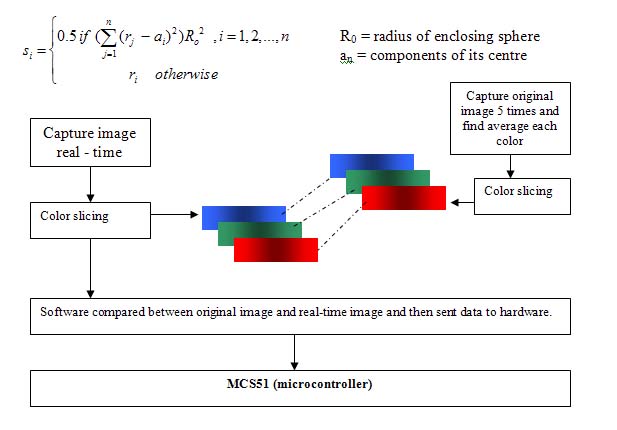

IMAGE PROCESSING

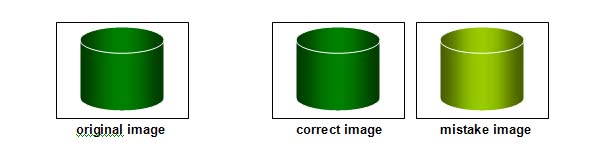

At first, Software would like to collect original picture for compare type real-time. Pictures use RGB model. This is average RGB by separate red, green and blue by using color slicing. Color slicing highlighting a specific rage of colors in an image is useful for separating objects from their surrounding. Saving original image is capture 5 times and finds average each color.

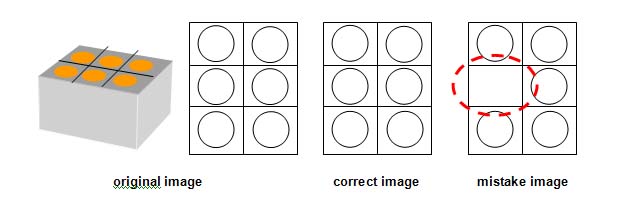

Experiment

2.

Detecting color of products.